Black Diamond

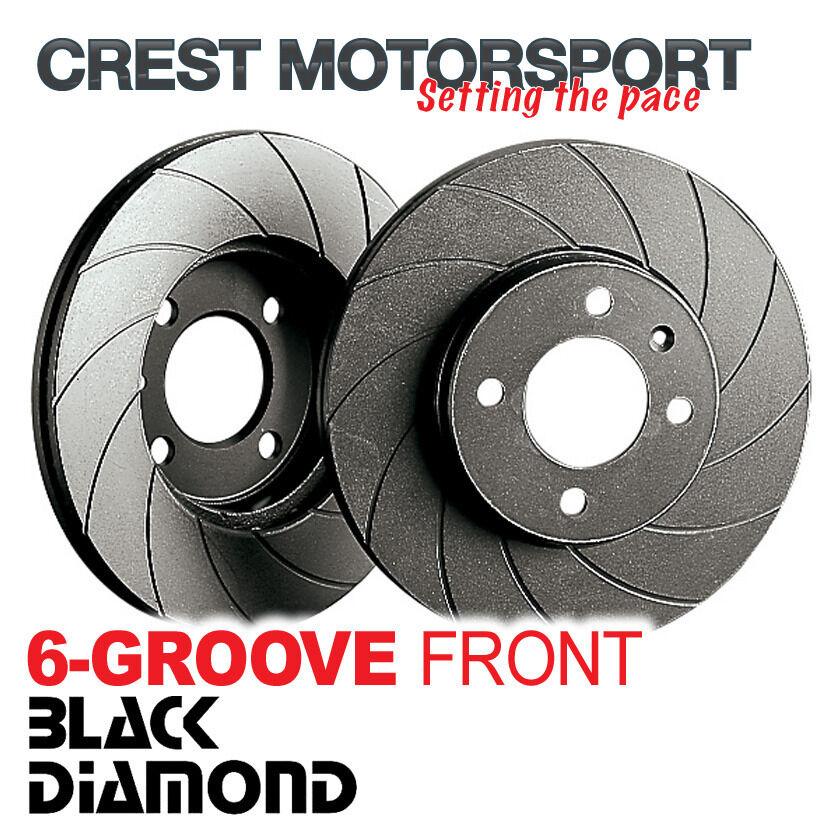

BLACK DIAMOND 6-Groove Vented Front Brake Discs (296mm) Grooved KBD603G6

BLACK DIAMOND 6-Groove Vented Front Brake Discs (296mm) Grooved KBD603G6

Couldn't load pickup availability

-

Description

Black Diamond Performance 6-Groove Brake Discs

Applications:

| Manufacturer | Model | Engine & Notes | Engine Size | Year |

| Dodge (USA) | Stealth | 3.0 | 2972cc | 10/89-96 |

| Dodge (USA) | Stealth | 3.0 Turbo | 2972cc | 10/89-96 |

| Mitsubishi | 3000GT (GTO) | 3.0 V6 (Z16A) | 2972cc | 8/92-99 |

| Mitsubishi | 3000GT (GTO) | 3.0 V6 Twin Turbo (Z16A)(ONLY suitable for models with 296mm front discs) | 2972cc | 8/92-99 |

Front/Rear: Front

Solid/Vented: Vented

Manufacturer's Part Number: KBD603G6

Brake Disc Range: 6-Groove

Which discs are right for me? Choose Diamond X-Drilled for extra cooling, Diamond 6- & 12-Groove for a more instant response and greater friction or Diamond's award winning Combination disc for the best of both with extra cooling, greater friction and instant response. (Click here to see the full range of Black Diamond brake discs)

NOTE: The eBay gallery image is used for illustration purposes only, actual disc appearance may differ from that shown.

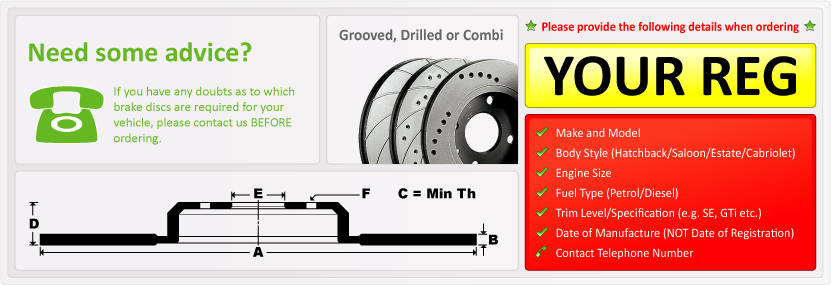

Disc Specification

A (Diameter in mm): 296

B (Thickness in mm): 30

C (Minimum Thickness in mm): 28.4

D (Height in mm): 45

E (Centre Bore in mm): 69

F (Number of Bolt Holes/Stud Pattern): 5+2

All brake discs are supplied as a complete axle set (one pair)

Incorrect specification for your vehicle? Click here to see the full range of Black Diamond brake discs listed for this make, model and variant.

Product Description

DIAMOND DISCS. These award winning brake discs are made to the most exacting standards using computer aided design and computerised production whether you buy a Diamond X Drilled range for extra cooling, Diamond 6- & 12-Groove range for more instant response and greater friction or Diamond's award winning Combination range for extra cooling, extra friction and instant response you will always get Diamond's unique compound and extra heat treatment to provide you with awesome braking performance.

The History of Black Diamond Products

Black Diamond Products was created in 1993. A British business, the company is dedicated to the improvement of performance car components in both quality of supply and manufacture.

With several performance components on offer, by far the most popular is the range of Black Diamond performance brake discs. After winning almost every award and test in the popular Max Power and Fast Car magazines they have proven Black Diamond discs to be the market leader!

Why Black Diamond?

Since their launch, the Black Diamond performance brake disc and pad range has gone from strength to strength. The first fast car test in 1995 in which Black Diamond was awarded the win against all the other major brands, it became clear that all the design and testing work prior to the launch was so very worth while. The 24 groove disc, the groove shape and profile and the post machining heat treatment all playing their part in making this product a world beater.

In 1996 Black Diamond were invited to take part in the first Max Power magazine awards test against all the other major world brands in the performance braking market, Black Diamond came out on top by such a huge margin that Max Power decided not to issue a second place prize! Their competitors were forced to wake up and in the next years awards they came equal first with another brand and in the next awards 1998 / 1999 after a Black Diamond pad compound tweak (Black Diamond Predator), Black Diamond won out right again and is still the current Max Power award holder. Now with over 1050 part numbers in the range it is believed to be the largest range of performance brakes in the world!

Fitting Help & Advice

Braking products are safety-critical components and vehicle manufacturers’ guidelines should always be followed.

Before attempting to fit replacement parts, always compare the new components with those removed from the vehicle, to ensure compatibility.

It is strongly recommended that brake pads and discs are fitted in axle sets. Replacing components on one wheel only can be extremely dangerous.

Before fitting replacement brake parts, ensure that all other braking system components, especially brake callipers - as well as those associated with steering and suspension - are not excessively worn or damaged otherwise disc warping can occur.

To ensure maximum performance and service life, new brake pads, shoes and discs require “bedding in”. This is best achieved by using the vehicle under normal driving conditions for at least 250 miles. Avoid violent braking from high speed or excessive light braking applications during this period.

Brake Disc Fitment

Before fitting discs it is vital to ensure that the vehicle hub is free of debris/dirt and rust deposits, otherwise brake judder may occur.

Disc and drum braking surfaces should be cleaned using a suitable brake cleaner before fitting (ensure that the brake cleaner manufacturer's safety instructions are followed). Please note: White spirit is NOT an acceptable cleaning product.

Brake discs can be specific to one side of the vehicle only, so always ensure the correct disc(s) are fitted to the correct side of the vehicle.

Before testing/driving the vehicle ALWAYS check the brake lines & calipers for signs of brake fluid leakage, if necessary top up at reservoir.